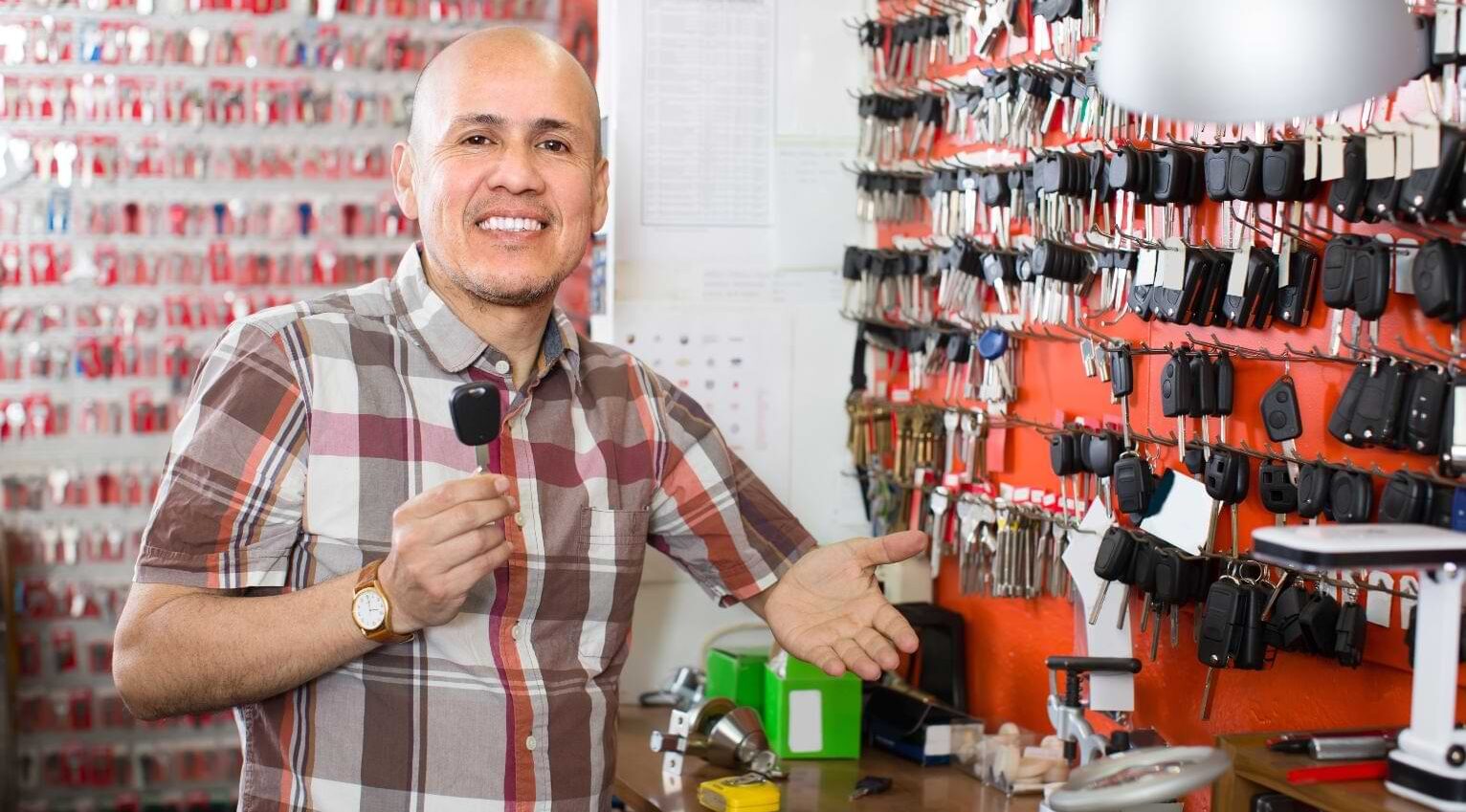

You probably expect to see a giant wooden pegboard with different key blanks grouped by function. Of course, it’s important to make sure all these blanks, not to mention the variety of tools locksmiths need, are right where they’re supposed to be. Many locksmiths manage their inventory with a single Excel sheet, some even walk around with a clipboard and a pen to do stock checks, and others claim they remember what they have. As a locksmith, you’re already spending most of the year on job sites or crammed into back-breaking positions in your van; you don’t need the added stress of poor stock management. Take your inventory control to the next level by finding the best locksmith inventory software.

Does your locksmith inventory suffer from these problems?

The first step in choosing a locksmith inventory software is finding the money leaks—the gaps in productivity that delay jobs, lose customers, and hurt your business’s reputation.

Common locksmith inventory issues:

- Using pen and paper: Managing all your keys, levers, deadbolts, and exit devices on paper is tedious, and there’s no room for mistakes. Without a locksmith inventory software – it’s only a matter of time before you’ll show up to a job without the right part, lose the job and get a bad review in the process. During emergencies, locksmiths need real-time inventory updates down to the container level. When you’re on the phone all day with frustrated customers, techs don’t have time to update information by hand or call into a busy office. Emergency dispatchers need immediate and accurate answers on your available inventory to quickly give customers a timeline of when the job will be completed.

- Product availability: More is usually better, but too much inventory can actually cost you money if you don’t book enough jobs. For example, take a multi-lock deadbolt, which can cost up to $200. If you order just 20 more deadbolts than you need, that’s $4,000 that could have been spent on advertising. On the flip side, if you show up to a job without the right parts, you’ll take a big hit on the price of the booking as well as your gas and travel expenses. Worst of all, the customer will be left with a bad impression and might even leave you a bad review on Yelp.

- Disorganized storage containers: If your van looks like your parents’ basement, you might waste valuable time searching for missing drill guns, only to realize you left them back home.

- Reliable software: You need good locksmith inventory software to organize thousands of keys and parts scattered across your trucks and office. Missing an expensive part or rare key kills a job instantly. It can take weeks for locksmith inventory to come in. In the meantime, your customers are locked outside their vehicles or homes and will leave poor online reviews. Your software must locate keys in their containers and notify you of low stock so you can reorder inventory.

Now that you get the gist, here are some tips on how to decide what software is best for you.

Tip #1: Find top reviewed locksmith inventory software fast

If you have inventory issues like the ones listed above—you’re bleeding money. Capterra is a software review site that can help locksmiths find their perfect inventory tool. Capterra has real user reviews from verified owners of locksmith businesses, a rating system, and side-by-side comparison charts on product features, pricing, customer support, and more. This saves your team from having to manually research each product or jump back and forth before you settle on the best software.

Tip #2: Avoid hurting your team’s performance with one mistake

Don’t exclude anyone in the decision process. Think of each person who needs to interact with your inventory and what’s most important to them. Inventory managers will want to pull detailed reports to track inventory levels in different locations, spot over- and under-stocked items, and predict profit or loss months in advance. Your field technicians will benefit just as much from inventory software, but they’ll have to learn the new tools on top of their locksmithing. Make sure to get their input on how much time it’ll take on the job or on weekends for them to adapt.

Tip #3: Prevent inventory disasters with these must-have tools

Here are some important features you cannot run your locksmith inventory without:

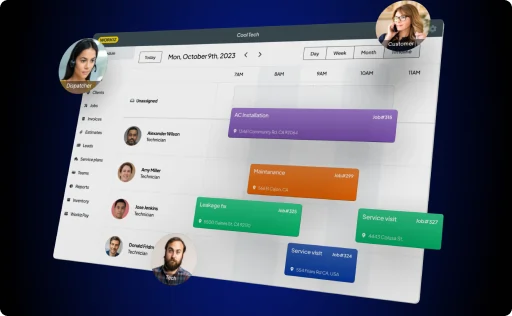

- Real-time inventory tracking: When all your inventory levels are just a couple of clicks away on your mobile phone or tablet, you can be ready for every job and avoid those annoying trips back to the office for parts. Workiz’s real-time tracking allows you to monitor returns, canceled orders, and movement between storage containers. It’ll also alert you when stock is running low, so you can stock up on key blanks, locks, and multi-lock deadbolts before you’re out of them entirely.

- Location management: Parts and tools could be stored at your main office, in the warehouse, or in any one of your service vehicles. Locksmiths need inventory software with a location management tool down to the container level – to track what’s been added or removed from each site.

- Access restriction: Prevent technicians from transporting the wrong inventory to job sites by assigning them to a single container or vehicle. When techs accidentally switch trucks, they’ll end up with the part they need in another car. You’ll either wait for the correct container to arrive or miss the job completely. Tracking and restricting storage containers guarantees your techs have the correct parts and vehicles on site.

- Integration: Inventory software should integrate with your calendar app, accounting system, email, and other operational tools. If it doesn’t, you’ll have to manually transfer data. The best software often comes with a list of apps it integrates with.

Tip #4: Answer these three questions to grow your business the smart way

- What’s the (actual) price? Pricing packages can change as you add on more users, and your monthly or annual fee can yo-yo throughout the year. Anticipate price changes if you’re growing your business.

- Will it scale? Your inventory control system changes when you take on more jobs, expand locations, or add new services, and abruptly switching software can hurt sales if it’s not compatible with your company or growth. If you plan to scale your business within the next 2-3 years, choose a software that will grow with you.

- Is it easy to learn? A new locksmith inventory software should be so simple to use – it’s just intuitive. For those of us who might need a little bit more help, users should also have access to ample customer support, video tutorials, and in-depth guides.

How much money can you save in 2 weeks?

Once you’ve picked a software, it’s time for your managers and technicians to test-drive it and examine the results. Set a few realistic goals to improve your inventory system and see if the software can deliver value.

Workiz is a locksmith software scheduling, dispatching invoicing, and inventory software that was created by and for locksmiths. Workiz was created by locksmiths who know what it takes for your locksmith business to succeed!

Service pros that use Workiz make 22% more revenue, and both inventory management experts and non-technical team members find it easy to use. What could a similar increase in profits do for your locksmith business?

We’re offering up a 7-day of our locksmith inventory software so you can find out for yourself. Check it out, and let the results speak for themselves.